Designer training

One-day training for tool designers with the following subjects: selection of the appropriate measuring points; choosing the necessary Cavity Eye devices; planning and modelling of the modifications necessary to install the components into the mold.

Toolshop training

One-day training for mold maintenance and electrical maintenance person with the topics of installation of Cavity Eye mold-side devices, performing pre-installation checks, mold testing after installation, detecting and eliminating errors.

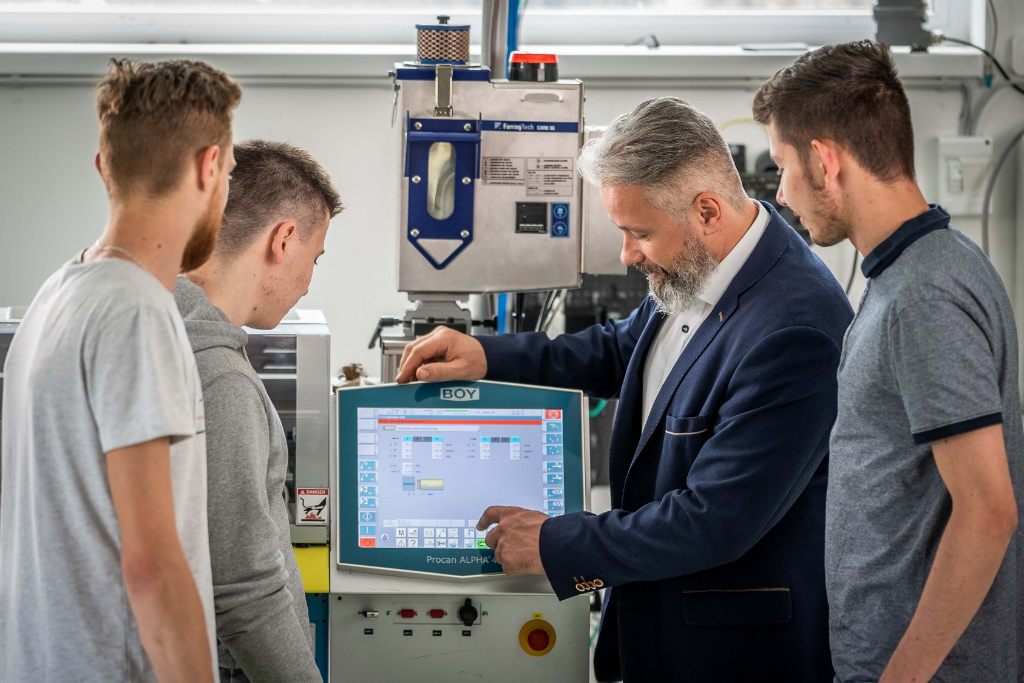

Application and technology training

One-day training for machine setters, technologist, injection molding engineers to learn about and use the Cavity Eye measuring system; understand pressure curves and determine what information can be gained from it and how to use it in everyday production; and how to set injection molding process based on cavity pressure measurement.

Advanced pressure measurement training

One-day training for machine setters, technologist, injection molding engineers where they learn about how to use cavity pressure measurement during process setting and optimalization; how to use the gained data for troubleshooting and root-cause analysis; shor and long term data analysis and case studies are presented as well.

This training is recommended for those who have already participated in an Application and Technology training.

Installation training for maintenance

One-day training for machine maintainers and electricians. The topic is the installation of the measuring system on the injection molding machine, checking the operation of the devices, identifying errors and troubleshooting.

The training topics are available to download after login/registration.

See the training dates!