The biggest part of the moulding cycle is the cooling phase. This usually consumes 50-70% of the total cycle time and determine the final part quality. It is a desire to make consistent parts with the lowest cycle time possible. Have you ever had a problem because of cooling? Siginifcant number of moulding failures related to cooling problems:

• Unsuccessful mould startup

• Did not change anything but the part dimensions are out of the tolerance

• Water stopped to flow

• Overheated mould, parts stucked in

• Undetected water leakage

• Scrap and unstable production

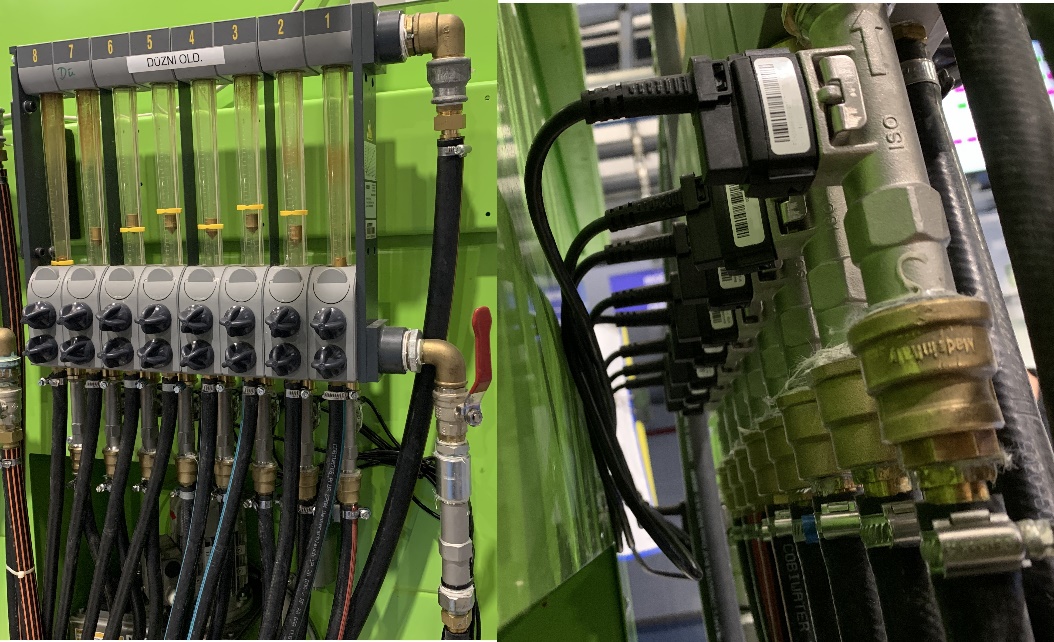

Sometimes a mould have over 30-50 cooling circuits. The only place where we can have a feedback is the tempering device. It can measure the water flow, pressure and temperature of the coolant but does not give feedback to the individual circuits. Multiple cooling cirtuits are gathered for one tempering device – parallel or serial joints are used. If we have parallel connection we do not have any feedback if a circuit is closed. If we have serial, the flow rate drops down and the cooling will not be efficient.

Besides that deposits from the cooling water continuously contaminate the cooling circuits in an injection moulding tool. These deposits, rust and fur gradually restrict the internal diameter of the cooling circuits and reduces the flow unnoticed over time. This will cause problems with the flow rate, problems that are only rarely detected by standard flow controllers. The consequence is an increased production of scrap parts.

„Seeing is beleiving” – Measure what you want to control

Cavity Eye Water Flow Monitoring let you keep control your tempering process – identify and react based on data not by feelings. We offer a solution to control the water circuits and measure the flow rate, temperature and pressure as well.

This technology helps to avoid unpredicted losses in costs and can reach a higher level of production quality. Tired of burning up money and resources to identify what is the problem? Want to open for higher quality part production but the process stability is not enough? Here is the solution!

Cost saving

• Identify failures immediately

• Wrong pipe connection order

• Closed tap

• Closed/clogged circuit

• Not enough flow rate – avoid overheating inserts

• No more unsucessful mould startup – Test in the toolshop

• No more scrap production – Machine stop and alarm system (e-mail)

Technology Benefits:

• Guarantee the same tempering conditions – Same part quality!

• Set process tolerances and references – Identify changes, act respectively!

• Maintenance according to measured data – Plan, act and save money!

• Tempering devices

• Fittings, tubes, moulds

• Long term data analysys – Reach the best process capability and upgrade your equipments based on facts!

• Cavity Eye Water Flow Monitoring can be easily retrofitted to the existing water flow regulators of your injection moulding machine and works extremely reliably.