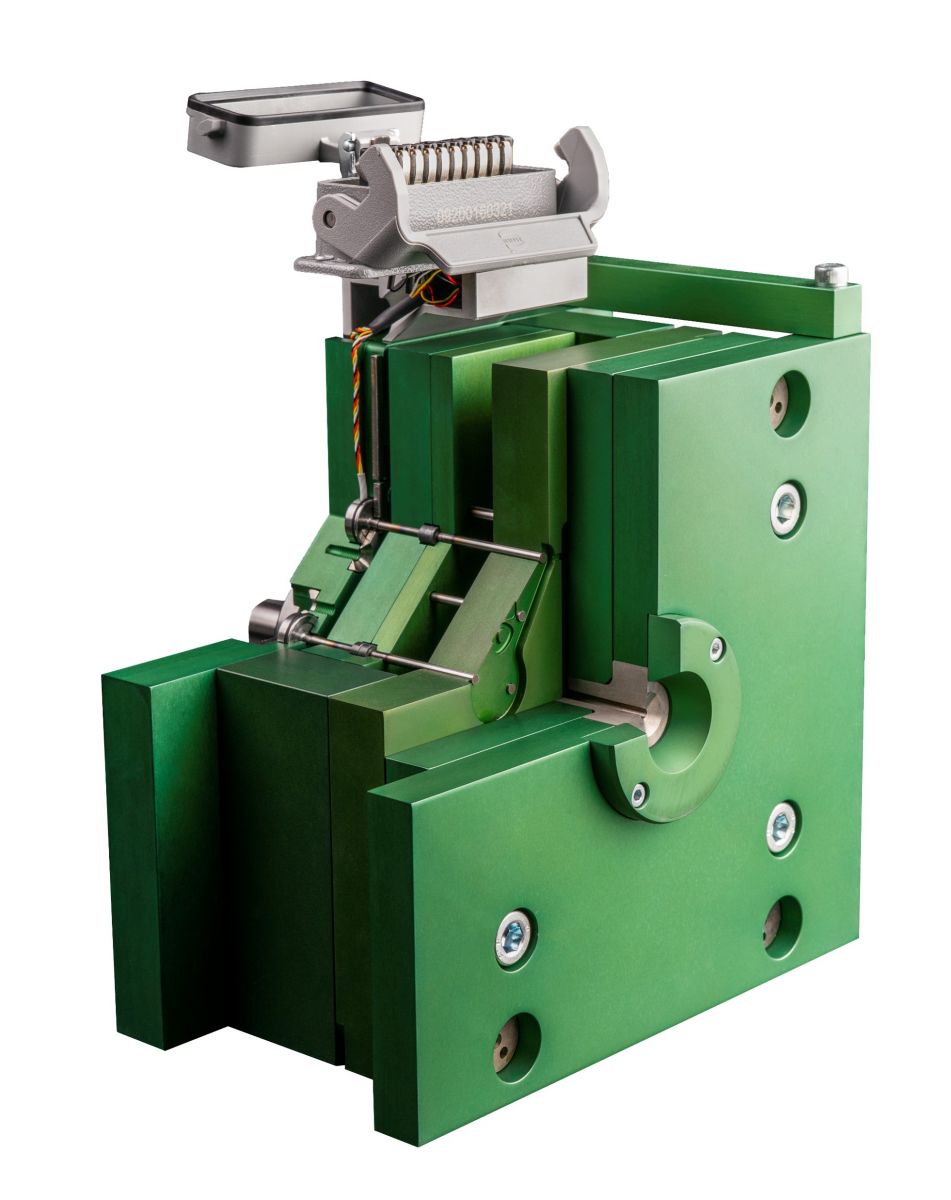

There are two common methods for sensor installation. In case of direct method, the flush mound sensors are installed by tight fit directly to the mould cavity. In the industry this method is known as the more punctual one, but the sensor’s precision changes with every maintenance and installation. Because of the tight fit the sensors are continuously under preload, and this has also a negative effect on accuracy. By the indirect method, the sensors are placed in the ejector plate. With the movement of ejector plate the sensors are moving as well, which can cause damage of the sensor and loss of accuracy over time.

In Cavity Eye we believe in using the indirect method, but we install the sensors into the clamping plate instead of the ejector plate. Behind the ejector pin a transfer pin is connected by loose fit, which transfers the force from the cavity pressure to the sensor head like a domino system. It is important to find the optimal length for the transfer pin to avoid preloading the sensors. Because of the easy fit the sensors there is a cushion around it, so friction has no effect on the measurement accuracy. The sensors can be installed into the clamping plate from two directions: front or rear. We usually use the rear-installed design, because the manufacturing process is simpler this way.

Max. 5 kN

.PNG)

Max. 40 kN

The Cavity Eye newly developed more precise, durable, water and shock resistant sensors are available. The company offers sensors in different diameters (15 and 26 mm), which have a maximum load range of 1 to 40 kN.

The pressure sensors operate on an electro-resistive principle, which is one of the oldest and most stable measuring methods. Cavity Eye uses only indirect sensors. From our experiences, the indirect measurement is much more precise, than the direct measurement. Using indirect measurement results in no need for sensor maintenance during the whole lifetime of the mold. Thanks to the sensor geometry we designed, the sensor installation is as easy as it gets! The final form of the sensors was achieved with years of hard work and development, so you get the most reliable source of information about your mold.

The brand name of the new type sensor is RC, which refers to Ring Cell because the sensors have a rubber ring around the diameter of the sensor which is aiming to help the following:

• Simplify the mold modification process

• Eliminate the fitting problems caused by the radius of the bottom of the sensor pocket

• More precise positioning of the sensors inside the pocket

• Enables smaller manufacturing precision and larger tolerances

Every sensor type has an item number, for example RC-15-1— where RC refers to the type of the sensor, 15 refers to the diameter of the sensor in mm and the last number refers to the maximum load: 1 kN. The possible two characters at the end of the code refers to the operating temperature of the sensor. Every sensors has a high-temperature range variation (HT) which is capable of measuring up to 200°C.

Please note that we are not distributing the PC15 type sensors. The following table helps you in choosing the right sensor for your mold.

Type of sensor

Maximum load [kN]

Maximum mould temperature [°C]

Diameter [mm]

Height [mm]

Max. ejector pin Diameter / Area [mm] / [mm2]

RC15-1

1

150

15

8

3 / 7

RC15-1-HT

1

200

15

8

3 / 7

RC15-5

5

150

15

8

6 / 28

RC15-5-HT

5

200

15

8

6 / 28

PC26-20

20

150

26

12

12 / 113

PC26-20-HT

20

200

26

12

12 / 113

PC26-40

40

150

26

12

20 / 314

PC26-40-HT

40

200

26

12

20 / 314

Up to 8 sensor channels

Up to 32 sensor channels

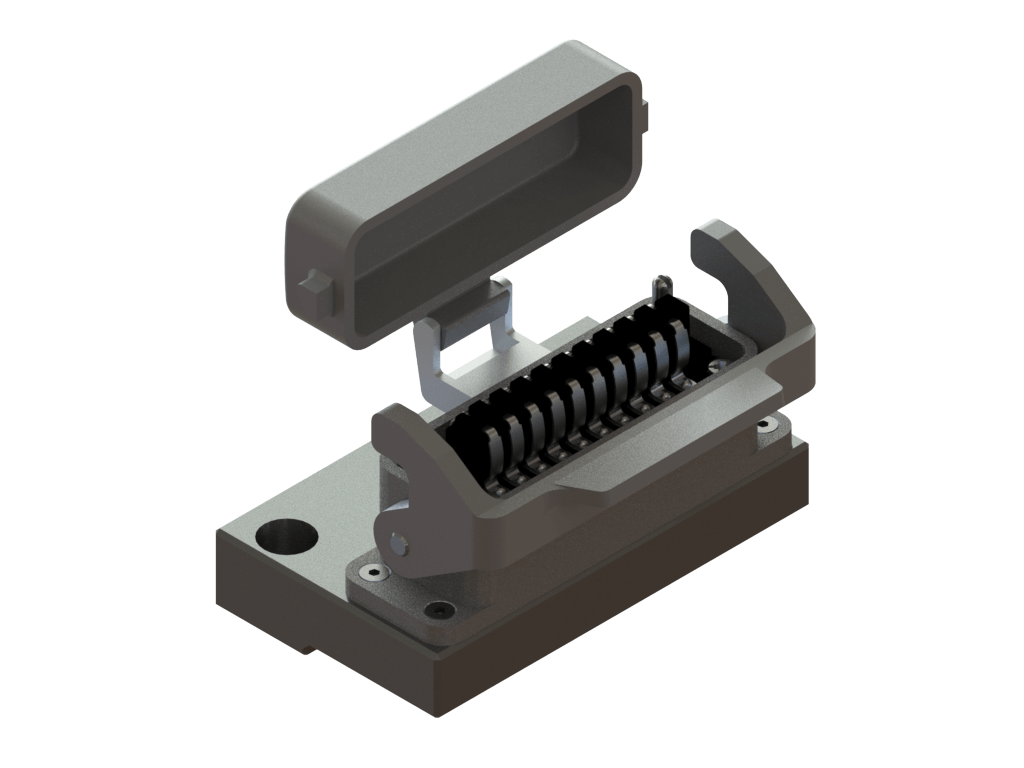

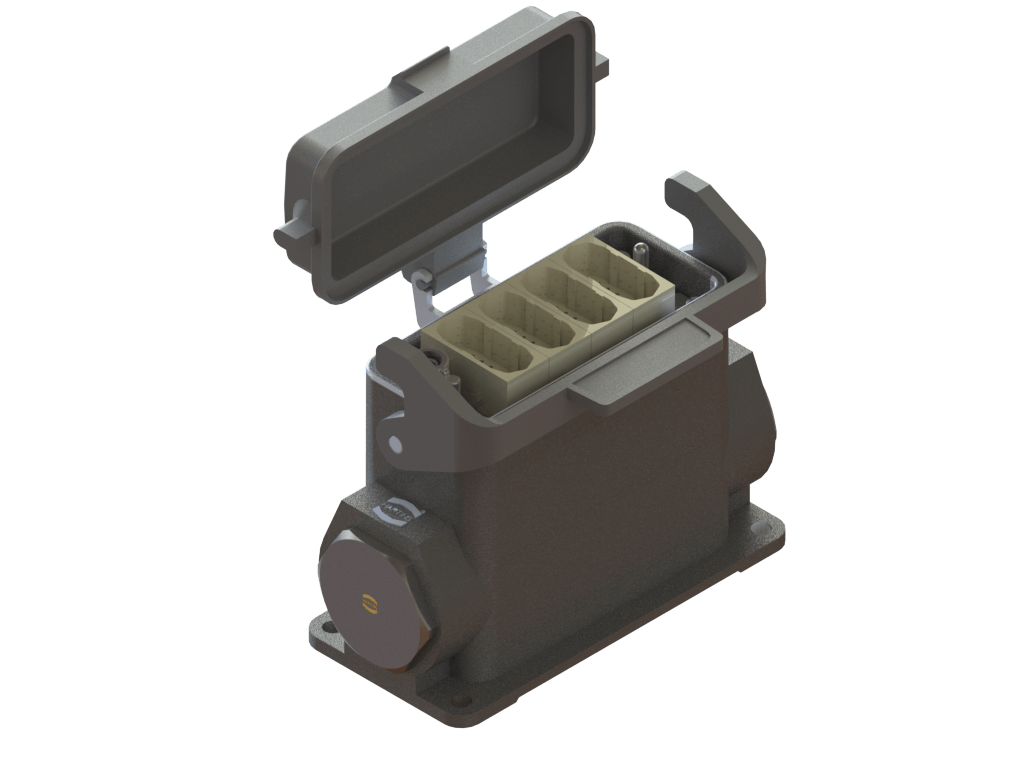

The Cavity Eye Mold Plug with Memory (MPM) socket was developed for the Injection Molds equipped with Cavity Eye pressure sensors. The wiring of the sensors takes place in this device, and it is also the counterpart of the Cavity Eye Smart Measuring Plug (SMP). This socket is equipped with a special, integrated memory, and responsible for storing the data of the molds and the Cavity Eye sensors. The memory can also contain the production data of the mold, for example: reference curves, tolerances, pin diameters, cavity IDs, etc.

There are two types of Mold Plugs you can choose from, depending on how much sensor signal is required to handle. MPM8-B type can be used up to 8 sensors. Over 8 sensors and up to 16 sensors 2 MPM8-B device can be applied. In case of higher sensor number, the MPM32-A device can be used. It can handle 32 sensors at the same time. In case of using more, than 32 sensors but maximum 64 sensors, 2 MPM32-A device is the right choice. The production starting and restarting procedure is getting quicker and easier with the memory in the MPM. You only have to upload memory content once, and the mold can be transferred to any injection machine afterwards, because the information is moving with the mold.

The following table helps You in choosing the right MPM socket.

Type of socket

Max. number of sensors

Operating temperature [°C]

Dimensions [mm]

MPM8-B

8

0 – +80

96×93×45

MPM32-A

32

0 – +80

127×140×57

The Smart Moulding Control (SMC) is an online, real-time quality and production monitoring system, which measures the cavity pressure in injection moulds and controls the production. New generational product monitoring and automatic injection moulding machine controlling is available with our pressure measurement system every day of the week for the 0 ppm scrap rate! SMC offers you a complete system that can be used with up to 8, 16, 32 or 64 pressure sensors.

If you want a measuring system which holds the important information about the mould in the mould socket, so you do not lose any of them while moving the mould, the Cavity Eye Smart Moulding Control is the best choice!

If you want an online, real-time quality and production monitoring system, which measures the cavity pressure in injection moulds and controls the production, moreover creates the possibility for analysis and statistic reports from the measured data, choose Cavity Eye Smart Moulding Control!

System type

Max. number of sensors

System content

SMC8

8

1 pcs SMP8, 1 pcs SCP412, Central unit with touchscreen and accessories

SMC16

16

2 pcs SMP8, 1 pcs SCP412, Central unit with touchscreen and accessories

SMC32

32

1 pcs SMP32, 1 pcs SCP412, Central unit with touchscreen and accessories

SMC64

64

2 pcs SMP32, 1 pcs SCP412, Central unit with touchscreen and accessories

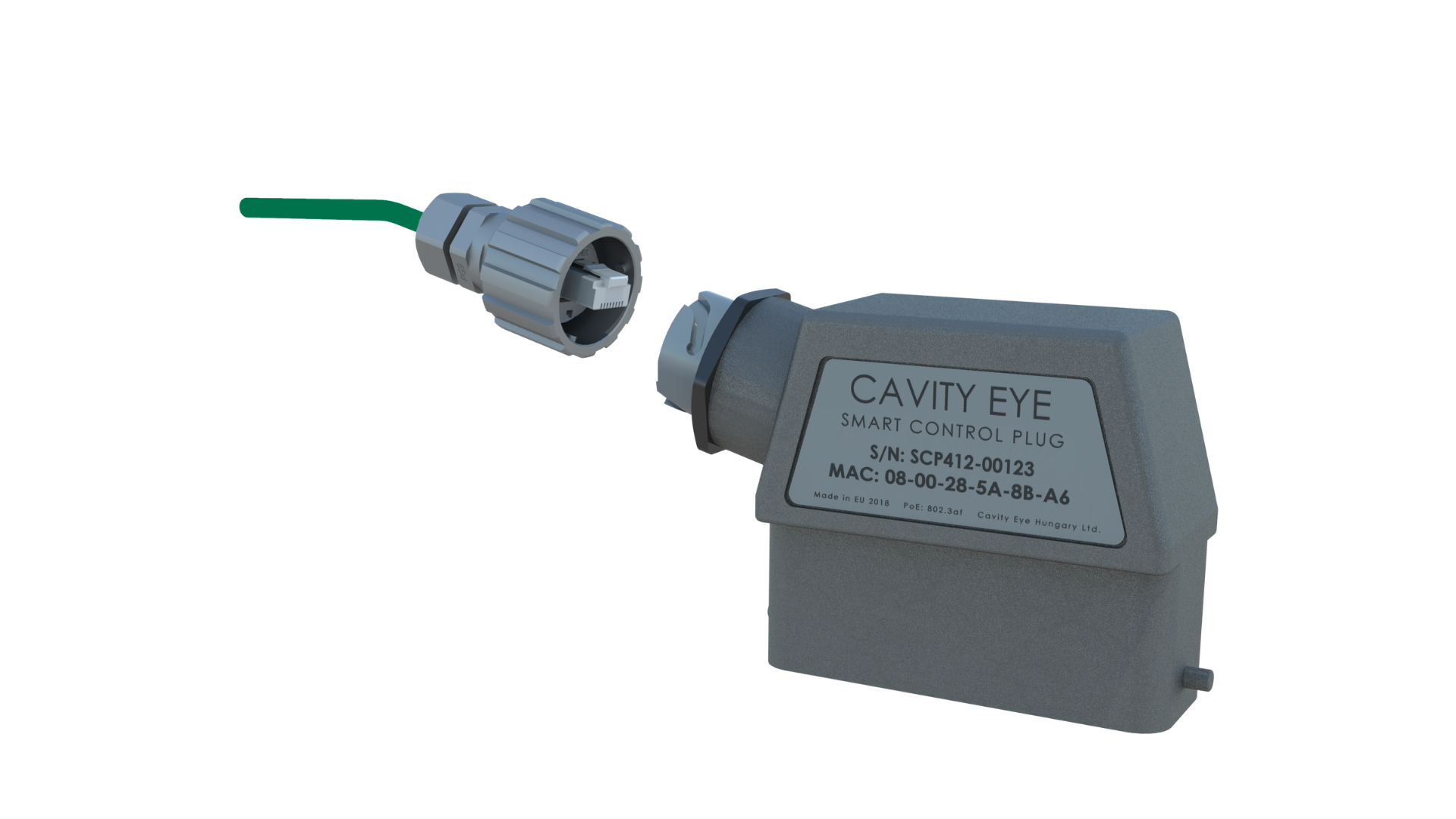

The main parts of the Cavity Eye SMC system are the Smart Measuring Plug (SMP) and the Smart Control Plug (SCP). These new generation Cavity Eye instruments are special, mobile industrial plugs, which are containing a measuring and controlling device with a microprocessor, so they can also operate independently from the system.

The Cavity Eye Smart Measuring Plug (SMP) is a special data processing unit, with the role of ensuring the communication with the injection molds equipped with Cavity Eye’s pressure cells. It receives and processes the pressure cell’s signals, then transmits the data to the Smart Control Plug through the central unit (PC and Switch). The memory reading/writing, the sensor signal processing and forwarding are also accomplished by the SMP device. The mold’s cavity pressure is measured by the pressure cells and the signals are received by the SMP, and the processed signals are forwarded to the software on the PC. There are two types SMP according to how many sensors you want to use in the system. The SMP8 is able to process data up to 8 sensors, while the SMP32 is the right choice up to 32 sensors. The SMP is the counterpart of the MPM devices.

The Smart Control Plug is communicating back and forth with the Injection Molding Machine with 24 V digital signals. The device receives the signals from the injection molding machine, processes and transmits them to the central unit. Furthermore, it is responsible for transforming the signals sent by the Cavity Eye system to 24V signals and forwarding them to the IMM. The device can control bad part sorting, detect the cycle start, stop the injection machine in case of an error and also can control nozzle valves of the mold.

The different SMC systems accessories are always the same. Only the type and the number of SMP devices are the difference. You can extend the number of measuring plugs or even change the type freely, thus you can use an already owned SMC system not just one, but any number of moulds.

SMP8

SMP32

Dimensions [mm×mm×mm]

110x36x70

142x43x80

Maximum number of sensors

8

32

A/D resolution

32 bit

32 bit

Sampling rate

100 Hz

100 Hz

Operating temperature range

-40..+85 °C

-40..+85 °C

Power supply

48 V (IEEE 802.3af PoE standard)

48 V (IEEE 802.3af PoE standard)

SCP412

SCP442

Dimensions [mm×mm×mm]

110x36x70

110x36x70

Number of input

4

4 digital + 2 analog

Number of output

12

4

Operating temperature range

-40..+85 °C

0..+65 °C

Power supply

48 V (IEEE 802.3af PoE standard)

max. 56 V (IEEE 802.3af)